PACHISLOT

- 1 Mounting of the LCD

- 2 Mounting of the front unit

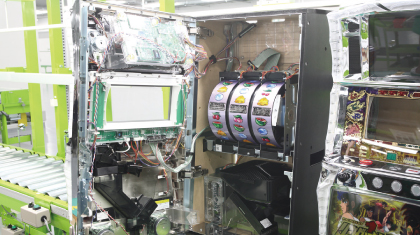

- 3 Mounting of the hopper and reel

- 4 Operation inspection

- 5 Finished product inspections

- 6 Registering links

- 7 Shipment

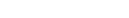

Pachislot machine manufacturing process

A front unit is loaded onto the dedicated line.

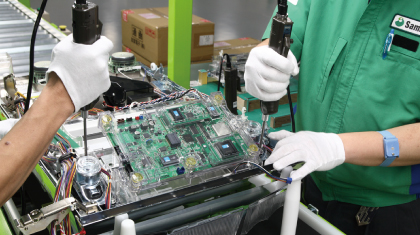

The LCD unit, which has passed through a static-eliminating air blower, is mounted and fastened, and then each harness is connected.

The front unit is combined with the back side box unit. Each harness is routed and connected with the greatest care.

The hopper and reel units are mounted.

Here again, each harness is routed and connected with the greatest care.

The assembled pachislot machine is next subjected to an operation inspection on the LEDs and each unit, using a test PWB.

After passing the operation inspection, the machine is fitted with its main PWB, and finally passes to the final inspections.

A pachislot machine that has passed all the inspections has a NICHIDENKYO certificate and a NIKKOSO patent license applied.

QR codes applied to each unit and the main PWB are scanned, links to the certificate number are registered, and the shipment destination and the date of manufacture are placed under uniform management.

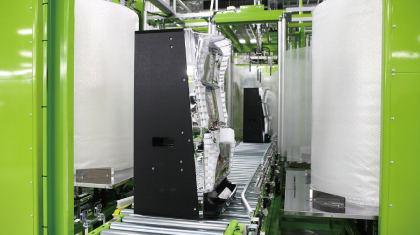

The finished pachislot machine is automatically packaged, has a shipping label applied, and is then sent to a distribution center.

It then waits to be delivered to the customer.

* QR Code is a registered trademark of DENSO WAVE INCORPORATED.